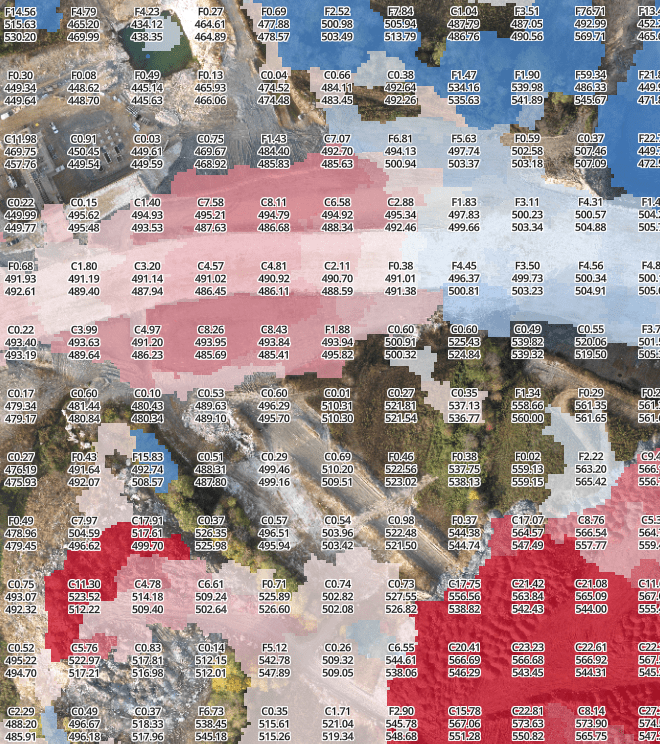

Know when others guess.

Ground-truth quantities, tonnages, and production.

Captured via drone. Sent right to your inbox.

Reports and Industries

Construction

Quantities, production, WIPs

Mining and Materials

Inventory and production

Oil/Gas and Others

Topography, slip detection, etc

Want to see some sample data or quantity reports? Click here to contact us.

How it works

Skip the drone hassle with our Reports Service. We’ll send a legally-certified pilot to your site, process the data, generate the reports, and send them to your inbox.

Skip the data processing headache with our Software Service. Upload your imagery to SiteIQ after you fly your jobsite. We’ll process, store, and manage the data. You can generate unlimited reports for unlimited users online.

Which one is right for you? Learn more.

Services

| Report Service | Software Service | |

|---|---|---|

| Fly whenever you please | Schedule flights instantly with Geohub. | N/A |

| Fly the drone & capture imagery | Our 107-certified pilot will fly an RTK aircraft | You can fly RTK/PPK/GCPs |

| Stitch the imagery into 3D | SiteIQ will process, manage, and store the data | SiteIQ will process, manage, and store the data |

| Generate and share reports | They’ll get automatically emailed out | You can generate unlimited reports for unlimited users |

Want more details on the tech? Learn more.

RTK vs PPK vs GCPs – we work with them all, but why is RTK best?

| Vertical accuracy in the data | Real-time accuracy assessment | Utilize existing base stations | Base station range | # of GCPs required | Compatible with site GPS calibration | |

|---|---|---|---|---|---|---|

| RTK | <0.1’. Yes. Really | Yes | Yes | 1-3 miles | 1 every 100 acres | Yes |

| PPK | 0.1-0.3’ | No | Sometimes | 5-10 miles | 1 every 50 acres | Yes |

| GCPs | 0.2 – 1’ | No | No | N/A | 5-10 GCPs every 100 acres | Yes |

Do you want to see the accuracy conclusions from our customers’ tests? Click here to request more information.

Sensors

| Camera & photogrammetry | LIDAR | |

|---|---|---|

| File outputs | Imagery, point cloud, contours | Point cloud, contours |

| Vertical accuracy | 0.1′ | 0.1 – 0.3′ |

| Use cases | Hard surfaces & bare earth | Topos underneath vegetation and tree canopy |

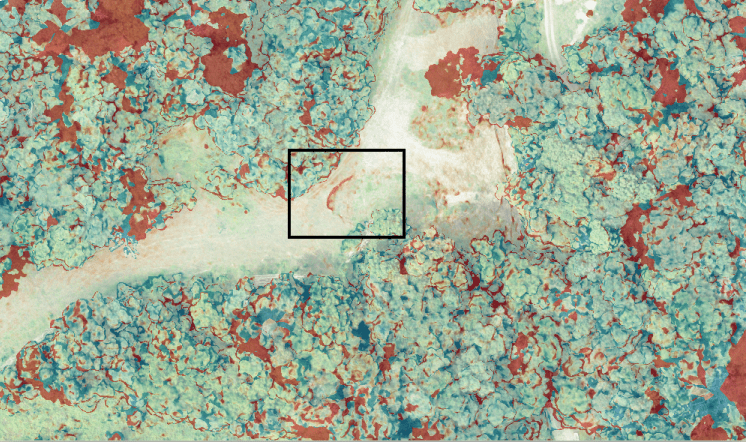

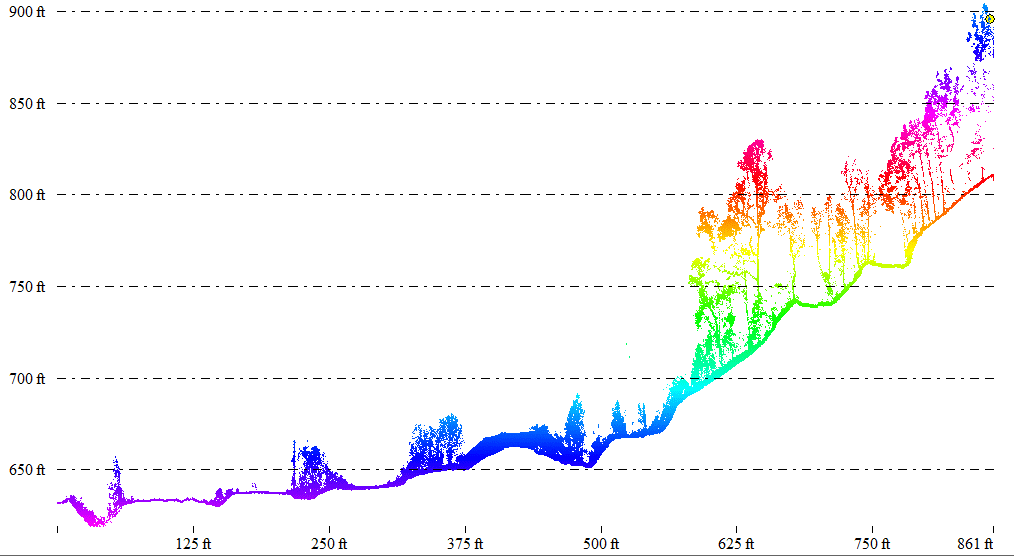

Cross-section of tree canopy and surface below

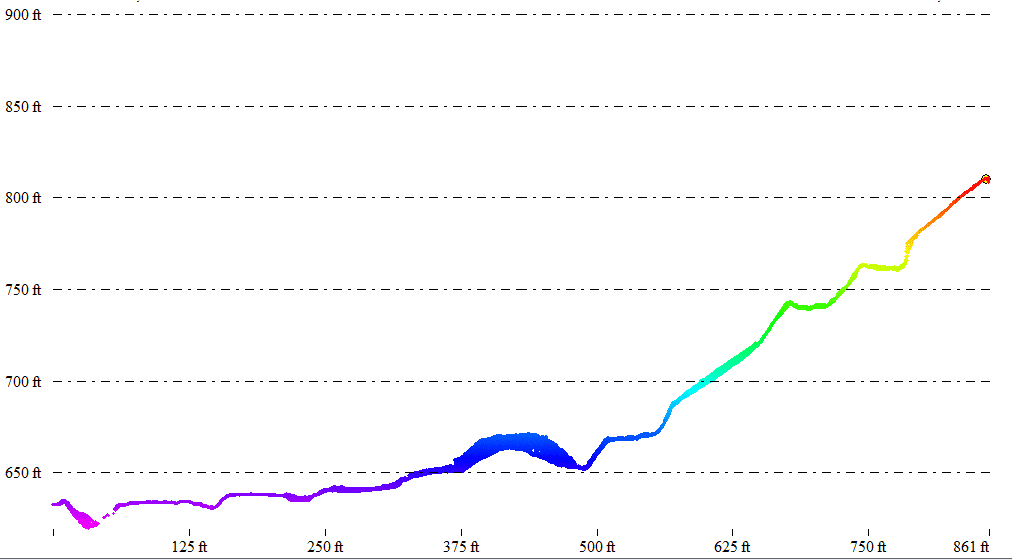

Classified surface beneath tree canopy

Want to see more sample LIDAR data sets? Learn more.